Sika Icosit KC 340/7, 2-Part Polyurethane Grout for Track Baseplates, Interior, Black, 6 kg

Sika

Sika is a global leader in specialty chemicals for the construction and industrial sectors. The company develops and supplies innovative products and systems for bonding, sealing, damping, reinforcing, and protecting structures. With a strong focus on sustainability and performance, Sika serves a wide range of applications including concrete production, waterproofing, roofing, flooring, and structural strengthening.

Read more| 2-part polyurethane grout under discrete baseplates of main-line tracks Sika Icosit KC 340/7 is a flexible 2-part polyurethane polymer resin grout. It is designed as a vibration absorbing, load-bearing, flexible grout for the precision alignment of rails, turnouts/switches etc. Sika Icosit KC 340/7 is also used for fixing track components to rigid substrates such as concrete slabs, steel bridge decks and tunnel invert slabs.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

UsageAs a noise and vibration reducing grout under discrete baseplates of main-line track sections.Advantages

Packaging

ColourBlack | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

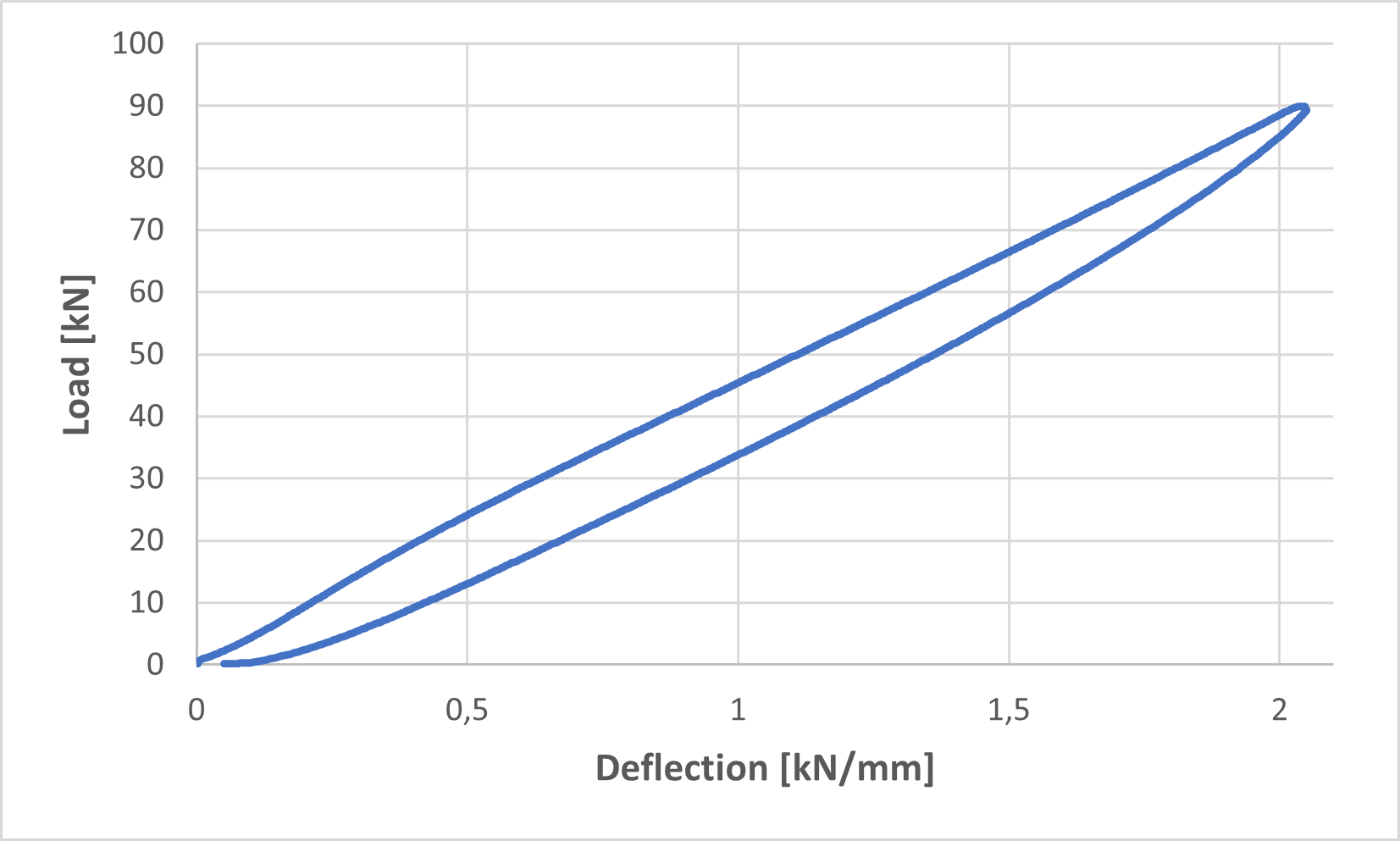

Technical Information Shore A Hardness 75 ± 5 (after 28 days) (ISO 868) Shore hardness assists with material identification and assessing the curing progress on site. Compressive stiffness Load-Deflection Diagram Static stiffness determined according to DIN 45673-1. Test specimen dimensions: 360 × 160 × 25 mm (pure material value measured without rail) Preload: 1,000 N Testing speed: 2 kN/s Maximum load: 50 kN Bedding figure kstat = ~44 [(kN/mm)/m] (±10 %)*, determined as per the secant method between 17 and 68 kN. *Deviation of the bedding figure and the curve are ±10%. Tensile Strength ~3,5 N/mm2 (ISO 527) Electrical Resistivity ~2,34 × 109 Ω·m (DIN VDE 0100-610 and DIN IEC 93) Service Temperature -40 °C minimum / +80 °C maximum short term up to +150 °C Chemical Resistance Long-term Resistant Against: Temporary Resistant Against: Short-term or No Resistance Against: Contact Sika Technical Services for specific information. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Application Information Mixing Ratio Part A : Part B = 100 : 15 (parts by weight) Layer Thickness 15 mm minimum 60 mm maximum Product Temperature Condition product parts before application preferably at ~+15 °C to assist with flow and curing speed Ambient Air Temperature +5 °C min. / +35 °C max. Relative Air Humidity 90 % maximum Substrate Temperature +5 °C min. / +35 °C max. Substrate Moisture Content Dry to matt damp Pot Life ~8 minutes at +20 °C After this time, the mixture becomes unusable. Higher temperatures will shorten pot life. Curing Time Tack-free ~2 hours at +20 °C Trafficable ~12 hours at +20 °C Curing Rate

Waiting Time / Overcoating On primer or coating at +20 °C

|