Sikasil WT-40, 1-Component Window Bonding Adhesive, Exterior, Black, 600 mL

SIKA

Sika is a global leader in specialty chemicals for the construction and industrial sectors. The company develops and supplies innovative products and systems for bonding, sealing, damping, reinforcing, and protecting structures. With a strong focus on sustainability and performance, Sika serves a wide range of applications including concrete production, waterproofing, roofing, flooring, and structural strengthening.

Read more| High-performance, 1-component window bonding adhesive Sikasil WT-40 is a 1-component, neutral-curing structural silicone adhesive with very high mechanical strength, for structural bonding of insulating glass units into window frames and for back-bedding applications.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||

PRODUCT BENEFITS

UsageSikasil WT-40 has a wide adhesion range on many substrates such as glass, (coated) metal, wood, PVC and many other substrates. In combination with its good mechanical properties, especially the high modulus of elasticity, this makes the adhesive most suitable for structural bonding of insulating glass units into window frames and for back-bedding applications. It is further suitable for highly demanding industrial bonding and sealing applications. This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be performed to ensure adhesion and material compatibility.Packaging

| |||||||||||||||||||||||||||||||||||||||||||||||||||||

Typical Product Data

| |||||||||||||||||||||||||||||||||||||||||||||||||||||

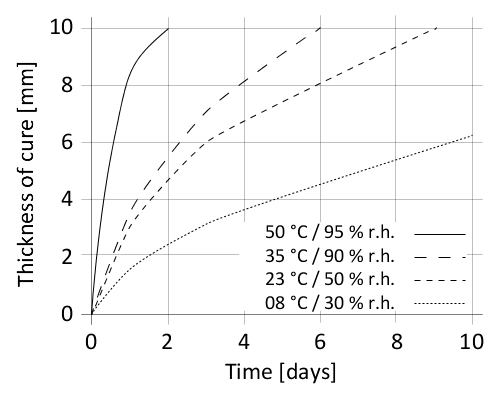

Technical Information CURE MECHANISM Sikasil WT-40 cures by reaction with atmospheric moisture. At low temperatures the water content of the air is generally lower and the curing reaction proceeds somewhat slower (see diagram 1). Diagram 1: Curing speed Sikasil WT-40 | |||||||||||||||||||||||||||||||||||||||||||||||||||||

Application Information Surface Preparation Surfaces must be clean, dry and free from grease, oil and dust. Surface treatment depends on the specific nature of the substrates and is crucial for a long lasting bond. Application The optimum temperature for substrate and sealant is between 15 °C and 25 °C. Sikasil WT-40 can be processed with hand, pneumatic or electric driven piston guns as well as pump equipment. For advice on selecting and setting up a suitable pump system, contact the System Engineering Department of Sika Industry. Joints must be properly dimensioned. Basis for calculation of the necessary joint dimensions are the technical values of the adhesive and the adjacent building materials, the exposure of the building elements, their construction and size as well as external loads. Joints deeper than 15 mm must be avoided. Tooling and finishing Tooling and finishing must be carried out within the skin time of the sealant or adhesive. When tooling freshly applied Sikasil WT-40, press the adhesive to the joint flanks to get a good wetting of the bonding surface. No tooling agents must be used. Removal Uncured Sikasil WT-40 may be re-moved from tools and equipment with Sika Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. Hands and exposed skin have to be washed immediately using hand wipes such as Sika Cleaner-350H cleaning towels or a suitable industrial hand cleaner and water. Do not use solvents on skin. Overpainting Sikasil WT-40 cannot be overpainted. Application Limits Recommended solution from Sika for structural glazing and window bonding are usually compatible to each other. These solutions consist of products such as Sikasil SG, IG, WS and WT series. For specific information regarding compatibility between various Sikasil products and other Sika products contact the Technical Department of Sika Industry. To exclude materials influencing Sikasil WT-40, all materials such as gaskets, tapes, setting blocks, sealants, etc., in direct and indirect contact have to be approved by Sika in advance. Where two or more different reactive sealants are used, allow the first to cure completely before applying the next one. The above mentioned Sika process materials may only be used in structural glazing or window bonding applications after a detailed examination and written approval of the corresponding project details by Sika Industry. |