Sikaflex-668, High-Performance Glazing & Assembly Adhesive Accelerated, Exterior, Black

SIKA

Sika is a global leader in specialty chemicals for the construction and industrial sectors. The company develops and supplies innovative products and systems for bonding, sealing, damping, reinforcing, and protecting structures. With a strong focus on sustainability and performance, Sika serves a wide range of applications including concrete production, waterproofing, roofing, flooring, and structural strengthening.

Read more| High-performance assembly, glazing adhesive and sealant with acceleration option Sikaflex-668 is based on Purform, an industry-leading polyurethane with less than 0.1% monomeric diisocyanate for better health protection and occupational safety. The Sikaflex-668 adhesive system is specifically designed for the rail industry. It is suitable for assembly bonding and glazing applications; its outstanding weathering durability and unique resistance to a wide variety of cleaning agents make it an ideal solution for use in exterior joints. Sikaflex-668 is compatible with Sika’s black-primerless bonding process. Sikaflex-668 can be accelerated with Sika’s Booster and PowerCure system.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||

PRODUCT BENEFITS

UsageSikaflex-668 is designed for assembly and direct-glazing applications in rail, the commercial vehicle industry and for the repair market. It exhibits excellent tooling and application properties. With its superior resistance to a wide range of cleaning agents combined with outstanding weathering durability, it can be used for exterior joints.Seek manufacturer’s advice and perform tests on original substrates before using Sikaflex-668 on materials prone to stress cracking. This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be performed ensuring adhesion and material compatibility. Packaging

| |||||||||||||||||||||||||||||||||||||||||||||||||||||

Typical Product Data

| |||||||||||||||||||||||||||||||||||||||||||||||||||||

Technical Information CURE MECHANISM Sikaflex-668 cures by reaction with atmospheric moisture. At low temperatures the water content of the air is generally lower and the curing reaction proceeds somewhat slower (see diagram 1). Diagram 1: Curing speed Sikaflex-668 CHEMICAL RESISTANCE Sikaflex-668 is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents. It is resistant to a wide range of rail cleaning agents if used according to the guidelines of the manufacturer. Some rail cleaning agents contain aggressive chemicals such as phosphoric acids which may influence the durability of Sikaflex-668 significantly. Therefore it is of highest importance to limit the exposure time to a minimum, observe correct dilution of cleaning agent and to perform a thorough rinsing after the cleaning process. Test newly introduced cleaning agents. The above information is offered for general guidance only. Advice on specific applications will be given on request. | |||||||||||||||||||||||||||||||||||||||||||||||||||||

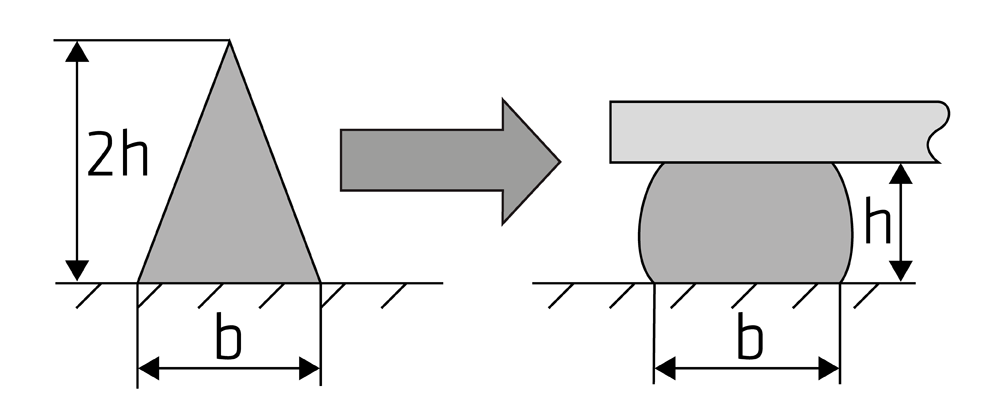

Application Information Surface Preparation Surfaces must be clean, dry and free from grease, oil, dust and contaminants. Surface treatment depends on the specific nature of the substrates and is crucial for a long lasting bond. All pretreatment steps must be confirmed by preliminary tests on original substrates considering specific conditions in the assembly process. Application Sikaflex-668 can be processed between 5 °C and 40 °C (climate and product) but changes in reactivity and application properties have to be considered. The optimum temperature for substrate and sealant is between 15 °C and 25 °C. Consider that the viscosity will increase at low temperature. For easy application, condition the adhesive at ambient temperature prior to use. To ensure a uniform thickness of the bondline it is recommended to apply the adhesive in form of a triangular bead (see figure 1).

Figure 1: Recommended bead configuration

For advice on selecting and setting up a suitable pump system, contact the System Engineering Department of Sika Industry. Tooling and finishing Tooling and finishing must be carried out within the skin time of the product. It is recommended using Sika Tooling Agent N. Other finishing agents must be tested for suitability and compatibility prior the use. Removal Uncured Sikaflex-668 may be removed from tools and equipment with Sika Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. Hands and exposed skin have to be washed immediately using hand wipes such as Sika Cleaner-350H or a suitable industrial hand cleaner and water. |