SikaMelt-209 HT, Cold Temp High Tack Pressure Sensitive Adhesive Hot Melt Adhesive, Interior

SIKA

Sika is a global leader in specialty chemicals for the construction and industrial sectors. The company develops and supplies innovative products and systems for bonding, sealing, damping, reinforcing, and protecting structures. With a strong focus on sustainability and performance, Sika serves a wide range of applications including concrete production, waterproofing, roofing, flooring, and structural strengthening.

Read more| Hot melt pressure sensitive adhesive with high tack at cold temperatures SikaMelt-209 HT is a multipurpose pressure sensitive hot melt adhesive based on thermoplastic rubber for a wide range of applications. SikaMelt-209 HT offers a large adhesion spectrum and a very high tack at cold temperatures

| ||||||||||||||||||||||||||||||||

PRODUCT BENEFITS

UsageSikaMelt-209 HT is suitable to be applied to papers, films and metal foils, textiles, foams and a wide variety of other materials. SikaMelt-209 HT is especially suitable for the manufacturing of self adhesive products. SikaMelt-209 HT is not to be used on substrates containing monomeric plasticizer.This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be performed ensuring adhesion and material compatibility. Packaging

| ||||||||||||||||||||||||||||||||

Typical Product Data

| ||||||||||||||||||||||||||||||||

Technical Information CURE MECHANISM SikaMelt-209 HT is a physically hardening adhesive. CHEMICAL RESISTANCE SikaMelt-209 HT is resistant to aqueous surfactant, weak acids and caustic solutions. | ||||||||||||||||||||||||||||||||

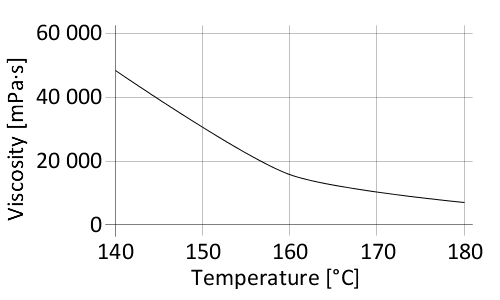

Application Information Surface Preparation Surfaces must be clean, dry and free from grease, oil and dust. Application With adequate processing equipment SikaMelt-209 HT can be applied directly or in a transfer method. It can be applied as film, dot, bead or spray application. For automated applications a suitable filter system is required. Due to the better adhesion performance the direct method is usually chosen whenever possible. The transfer method is often used in combination with substrates that are porous and absorbing such as foams or when they are sensitive to high temperature such as thin PE films. To protect the adhesive surface against dust, light and oxygen it is necessary to cover the adhesive film with silicone coated paper or foil. To meet the required application properties the adhesive viscosity can be adjusted by adapting the application temperature (see diagram 1).

Diagram 1: Viscosity as a function of temperature

During breaks SikaMelt-209 HT is to be processed as follows: For breaks ≥ 1 h the heating needs to be lowered to 80 °C and for breaks ≥ 4 h the heating needs to be switched off. Removal SikaMelt-209 HT may be removed from tools and equipment with Sika Remover-208 or another suitable solvent. Do not use solvents on skin. STORAGE CONDITIONS SikaMelt-209 HT has to be stored at temperature below 40 °C in a dry place. |