Sikaflex-298, Thixotropic Bedding Compound for Marine Use, Exterior, Brown

SIKA

Sika is a global leader in specialty chemicals for the construction and industrial sectors. The company develops and supplies innovative products and systems for bonding, sealing, damping, reinforcing, and protecting structures. With a strong focus on sustainability and performance, Sika serves a wide range of applications including concrete production, waterproofing, roofing, flooring, and structural strengthening.

Read more| Slightly thixotropic bedding compound for marine applications Sikaflex-298 is a slightly thixotropic 1-component polyurethane adhesive which cures on exposure to atmospheric humidity. It is used for Teak deck bedding.

| |||||||||||||||||||||||||||||||||||||||||||||||

PRODUCT BENEFITS

UsageSikaflex-298 is suitable for bonding deck covering materials made from synthetic resins (except polyethylene and polypropylene), and for bedding-in of teak plank decking laid on top of the sub deck surface. Suitable substrates include GRP, marine plywood, steel, aluminum sealed with an anti-corrosion coating (epoxy or polyurethane-acrylic based) and stainless steel.Sikaflex-298 has a longer skinning time as the Sikaflex-298 FC version and might be used where elevated temperature and/or higher humidity are expected. Sikaflex-298 is suitable for experienced professional users only. Test with actual substrates and conditions have to be performed to ensure adhesion and material compatibility. Packaging

| |||||||||||||||||||||||||||||||||||||||||||||||

Typical Product Data

| |||||||||||||||||||||||||||||||||||||||||||||||

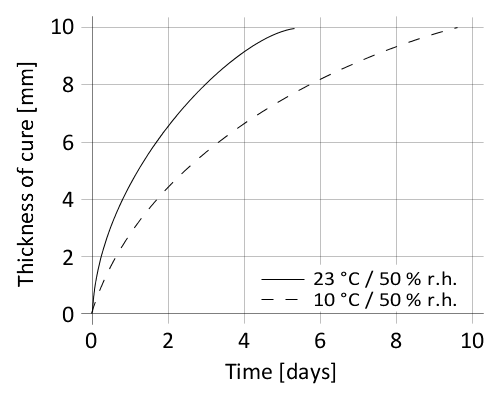

Technical Information CURE MECHANISM Sikaflex-298 cures by reaction with atmospheric moisture. At low temperatures the water content of the air is generally lower and the curing reaction proceeds somewhat slower (see diagram 1). Diagram 1: curing speed Sikaflex-298 CHEMICAL RESISTANCE Sikaflex-298 is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents. | |||||||||||||||||||||||||||||||||||||||||||||||

Application Information Surface Preparation Surfaces must be clean, dry and free from grease, oil, dust and contaminants. Application Sikaflex-298 can be processed between 10 °C and 35 °C but changes in reactivity and application properties have to be considered. The optimum temperature for substrates and adhesive is between 15 °C and 25 °C. The adhesive is applied over large surface areas with a notched spreader (notch depth approx. 4 mm). The consumption is approx. 1.2 l per m2. If the substrates to be bonded are impervious to moisture or if an accelerated rate of cure is required, the adhesive could be lightly sprayed with a water mist shortly before the substrates are joined together (use an aerosol spray or spray gun to apply approx. 10 g water per m2). Avoid air entrapment when joining the parts or filling joints. Apply firm pressure when bringing components together and keep the bond under pressure for at least 3 hours until the adhesive has set. The open time is significantly shorter in hot and humid climate. The parts must always be installed within the open time. Never join bonding parts if the adhesive has built a skin. Removal Uncured Sikaflex-298 can be removed from tools and equipment with Sika Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. Hands and exposed skin have to be washed immediately using hand wipes such as Sika Cleaner-350H or a suitable industrial hand cleaner and water. Do not use solvents on skin! |