SikaMelt-670, Polyurethane Hot Melt Adhesive for Assembly Applications, Interior

SIKA

Sika is a global leader in specialty chemicals for the construction and industrial sectors. The company develops and supplies innovative products and systems for bonding, sealing, damping, reinforcing, and protecting structures. With a strong focus on sustainability and performance, Sika serves a wide range of applications including concrete production, waterproofing, roofing, flooring, and structural strengthening.

Read more| Polyurethane Hot Melt for assembly applications SikaMelt-670 is a reactive polyurethane hot melt adhesive which cures on exposure to atmospheric humidity. With its short open time, high green strength and broad adhesion range it is best suited for fast assembly operations.

| |||||||||||||||||||||||||||||||||||||||||

PRODUCT BENEFITS

UsageSikaMelt-670 is especially designed for fast assembly applications in diverse areas. It is suitable for permanent bonding of polar plastics as well as for wood, foam, textiles, painted and primed steel. Non polar plastics like PP and PE can be bonded after proper physical pre-treatment. Typical application areas are Automotive interior trim and other industrial assembly operations.This product is suitable for experienced professional users only. Test with actual substrates and conditions have to be performed to ensure adhesion and material compatibility. Packaging

| |||||||||||||||||||||||||||||||||||||||||

Typical Product Data

| |||||||||||||||||||||||||||||||||||||||||

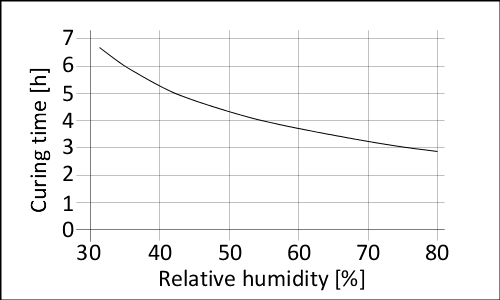

Technical Information CURE MECHANISM SikaMelt-670 cures by reaction with atmospheric moisture. At low temperatures the water content in the air is lower, which will result in a lower curing speed (see diagram 1). When bonding hydrophobic (e.g. PP) and/or moisture impermeable substrates a significantly longer curing time has to be taken into account. This applies especially on assembly applications with an adhesive thickness > 100 µm. For lamination applications of hydrophobic and/or moisture impermeable substrates the adhesive layer shall not exceed 100 µm. In such cases project related tests with original substrates and conditions are mandatory. Diagram 1: Curing time for 500 µm film CHEMICAL RESISTANCE SikaMelt-670 is resistant to aqueous surfactant, weak alkaline/acids solutions and temporarily resistant to fuels, solvents and mineral oils. | |||||||||||||||||||||||||||||||||||||||||

Application Information Surface Preparation Surfaces must be clean, dry and free from grease, oil and dust. Application With adequate processing equipment SikaMelt-670 can be applied as film, dot, bead or spray application. It is not recommended for roller coater application. For automated applications a suitable filter system is required. Removal Equipment and application tools can be cleaned with SikaMelt-009. Cured material can for cleaning purposes be swelled with SikaMelt-001 and needs to be removed mechanically (see also cleaning instruction). SikaMelt-670 may be removed from tools and equipment with Sika Remover-208 or another suitable solvent. Do not use solvents on skin. STORAGE CONDITIONS SikaMelt-670 has to be stored at temperature below 30 °C in a dry place. |