Sika Icosit KC 340/35, Polyurethane grout for embedded tracks (soft hardness), Exterior, Light Grey

SIKA

Sika is a global leader in specialty chemicals for the construction and industrial sectors. The company develops and supplies innovative products and systems for bonding, sealing, damping, reinforcing, and protecting structures. With a strong focus on sustainability and performance, Sika serves a wide range of applications including concrete production, waterproofing, roofing, flooring, and structural strengthening.

Read more|

2-part polyurethane grout for continuous embedded tracks (shore A 40)

Sika® Icosit® KC 340/35 is a flexible two-part polyurethane polymer resin grout that can be applied manually or by machine.

|

|||||||||||||||||||||||||||||||||||||||||||||||

UsageAs a noise and vibration reducing grout for continuous embedded tram or LRT track sections and road crossing applications.Advantages

Packaging

Refer to current price list for packaging variations. ColourLight grey |

|||||||||||||||||||||||||||||||||||||||||||||||

Technical Information

Shore A Hardness

40 ± 5 (after 28 days) (ISO 868) Shore hardness assists with material identification and assessing the curing progress on site.

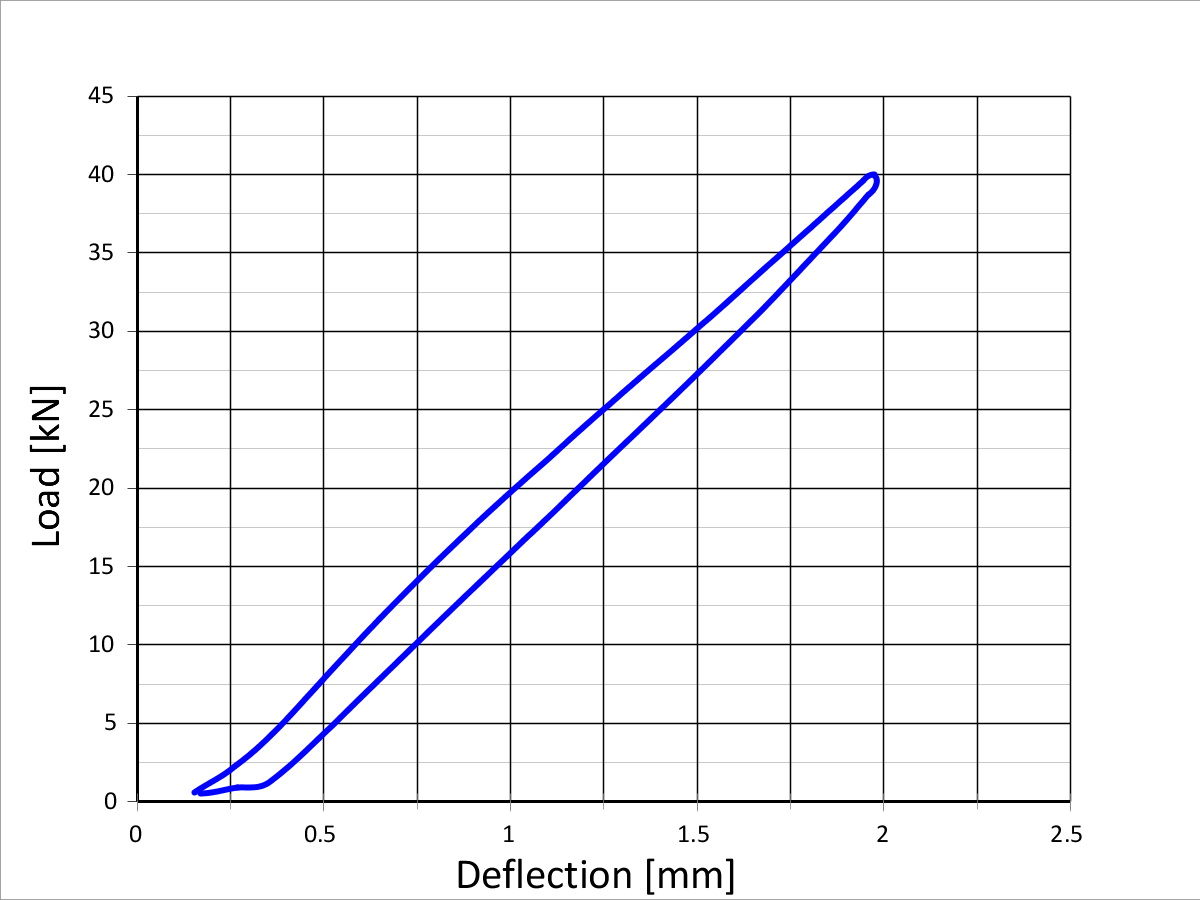

Compressive stiffness

Load-Deflection Diagram Static stiffness determined according to DIN 45673-1. Dimensions of test specimen 1000 × 180 × 25 mm; Spring index kstat = 25 kN/mm (± 10 %), determined as per the secant method between 4 and 32 kN.

Tensile Strength

~0,9 N/mm2 (ISO 527)

Electrical Resistivity

~1,5 × 109 Ω·m (DIN VDE 0100-610 and DIN IEC 93)

Service Temperature

-40 °C minimum / +80 °C maximum Short term: +150 °C maximum

Chemical Resistance

Long-term resistant against: Short-term resistant against: Short-term or no resistance against: Contact Sika Technical Services for specific information. |

|||||||||||||||||||||||||||||||||||||||||||||||

Application Information

Mixing Ratio

Part A : Part B = 100 : 12 (parts by weight)

Layer Thickness

15 mm minimum 60 mm maximum

Product Temperature

Condition product parts before application preferably at ~+15 °C to assist with flow and curing speed

Ambient Air Temperature

+5 °C minimum / +35 °C maximum

Relative Air Humidity

90 % maximum

Substrate Temperature

+5 °C minimum / +35 °C maximum

Substrate Moisture Content

Dry to matt damp

Pot Life

~11–12 minutes at +20 °C After this time, the mixture becomes unusable. Higher temperatures will shorten pot life.

Curing Time

Tack-free ~2 hours at +20 °C Trafficable ~24 hours at +20 °C

Curing Rate

Waiting Time / Overcoating

Waiting time between primer and Sika® Icosit® KC 340/35 at 20 °C:

|

,%20Exterior,%20Light%20Grey%20(Packing:%20179,2%20kg)?unique=2970614)