Sikaflex-508, Low Emission Multipurpose STP Sealant, Interior & Exterior, Black

SIKA

Sika is a global leader in specialty chemicals for the construction and industrial sectors. The company develops and supplies innovative products and systems for bonding, sealing, damping, reinforcing, and protecting structures. With a strong focus on sustainability and performance, Sika serves a wide range of applications including concrete production, waterproofing, roofing, flooring, and structural strengthening.

Read more| Low emission multipurpose STP sealant Sikaflex-508 is a low emission one-component isocyanate free sealant based on the Sika Silane Terminated Polymer (STP) technology which cures on exposure to atmospheric humidity. Sikaflex-508 meets the most severe environment, health and safety standards and sets a new benchmark in this technology.

| |||||||||||||||||||||||||||||||||||||||||||||

PRODUCT BENEFITS

UsageSikaflex-508 is a low modulus multipurpose sealant for internal and external applications. It adheres well to a wide variety of substrates and is especially compatible with foamed polystyrene foams (XPS). Seek manufacturer’s advice and perform tests on original substrates before using Sikaflex-508 on materials prone to stress cracking. This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be performed ensuring adhesion and material compatibility.Packaging

| |||||||||||||||||||||||||||||||||||||||||||||

Typical Product Data

| |||||||||||||||||||||||||||||||||||||||||||||

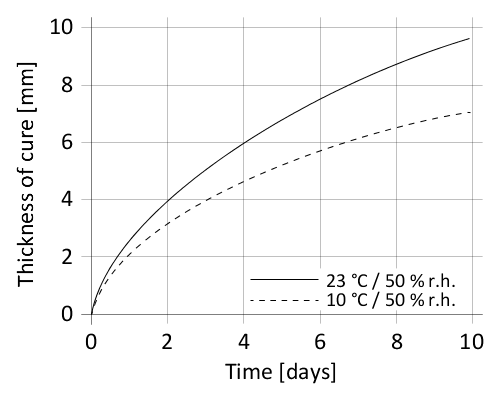

Technical Information CURE MECHANISM Sikaflex-508 cures by reaction with atmospheric moisture. At low temperatures the water content of the air is generally lower and the curing reaction proceeds somewhat slower (see diagram 1). Diagram 1: Curing speed Sikaflex-508 CHEMICAL RESISTANCE Sikaflex-508 is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents. | |||||||||||||||||||||||||||||||||||||||||||||

Application Information Surface Preparation Surfaces must be clean, dry and free from grease, oil, dust and contaminants. Application Place the unipack in the application gun and snip off the closure clip. Cut off the tip of the nozzle to suit desired joint and apply the sealant with a suitable caulking gun. Take care to avoid air entrapment in the joint. Tooling and finishing Tooling and finishing must be carried out within the skin time of the sealant. It is recommended using Sika Tooling Agent N. Other finishing agents must be tested for suitability and compatibility prior the use. Removal Uncured Sikaflex-508 can be removed from tools and equipment with Sika Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. Overpainting Sikaflex-508 can be overpainted within the skin formation time. 2 component epoxy paints are usually suitable. Other paints must be tested for compatibility by carrying out preliminary trials under manufacturing conditions. The elasticity of paints is usually lower than of elastomers what could lead to cracking of the paint film in the joint area. |