SikaTack PRO, Premium Auto Glass Adhesive Professional Use, Exterior, Black

SIKA

Sika is a global leader in specialty chemicals for the construction and industrial sectors. The company develops and supplies innovative products and systems for bonding, sealing, damping, reinforcing, and protecting structures. With a strong focus on sustainability and performance, Sika serves a wide range of applications including concrete production, waterproofing, roofing, flooring, and structural strengthening.

Read more| Premium choice for Auto Glass Professionals SikaTack PRO is a cold applied Automotive Glass Replacement adhesive offering 30 minutes Minimum Drive-Away Time (MDAT). It can be used all year round and is ideal for mobile or in-house applications.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||

PRODUCT BENEFITS

UsageSikaTack PRO is suitable for experienced professional users only. This product and related process information is designed for Automotive Glass Replacement. For other applications, tests with actual substrates and conditions have to be performed to ensure adhesion and material compatibility.Packaging

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||

Typical Product Data

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||

Technical Information CURE MECHANISM SikaTack PRO cures by reaction with atmospheric moisture. At low temperatures the water content of the air is generally lower and the curing reaction proceeds somewhat slower (see diagram 1). Diagram 1: Curing speed for SikaTack PRO CHEMICAL RESISTANCE SikaTack PRO is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

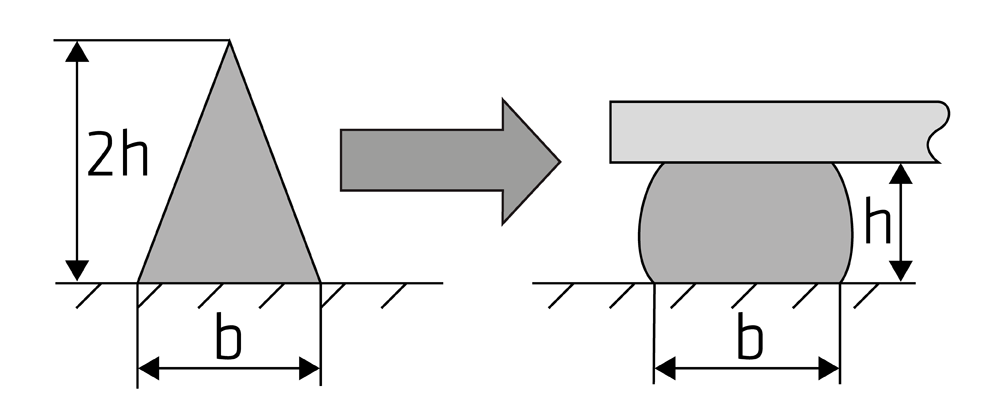

Application Information Surface Preparation Surfaces must be clean, dry and free from grease, oil, dust and contaminants. Application It is recommended to apply SikaTack PRO with a powerful battery operated application gun. Consider that the viscosity will increase at low temperature. For easy application, condition the adhesive at ambient temperature prior to use. To ensure a uniform thickness of the bondline it is recommend to apply the adhesive in form of a triangular bead (see figure 1). Figure 1: Recommended bead configuration

The open time is significantly shorter in hot and humid climate. The glass must always be installed within the open time. Never install a glass after the adhesive has built a skin. Removal Uncured SikaTack PRO can be removed from tools and equipment with Sika Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. Hands and exposed skin have to be washed immediately using hand wipes such as Sika Cleaner-350H or a suitable industrial hand cleaner and water. Do not use solvents on skin. |