Sikaflex-554 + SikaBooster S-50, Accelerated STP Adhesive for Assembly Bonding, Interior & Exterior, 23 L + 23 L

SIKA

Sika is a global leader in specialty chemicals for the construction and industrial sectors. The company develops and supplies innovative products and systems for bonding, sealing, damping, reinforcing, and protecting structures. With a strong focus on sustainability and performance, Sika serves a wide range of applications including concrete production, waterproofing, roofing, flooring, and structural strengthening.

Read more| Accelerated STP adhesive for assembly bonding Sikaflex-554 + SikaBooster S-50 is an accelerated Silane Terminated Polymer (STP) adhesive system especially designed for bonding large components in industrial assembly. It bonds well to a wide range of substrates with minimal pretreatment.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

PRODUCT BENEFITS

UsageSikaflex-554 + SikaBooster S-50 is suitable for joints that will be subjected to dynamic stresses. Suitable substrate materials are metals, particularly aluminium, metal primers, paint coatings, sheet steel, ceramic materials and certain plastics. It bonds well to a wide range of substrates with minimal pre-treatment. Seek manufacturer’s advice and perform tests on original substrates before using Sikaflex-554 + SikaBooster S-50 on materials prone to stress cracking. This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be performed ensuring adhesion and material compatibility.Packaging

Sikaflex-554

SikaBooster S-50

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

Typical Product Data

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

Technical Information CURE MECHANISM Sikaflex-554 + SikaBooster S-50 cures by reaction with the accelerator and largely independent from atmospheric moisture. For typical strength build up data at 23 °C see table below. Time [h] Lap-Shear Strength [MPa] 2 0.25 4 0.7 8 1.2 24 2 Table 1: Strength build-up Sikaflex-554 + SikaBooster S-50 CHEMICAL RESISTANCE Sikaflex-554 + SikaBooster S-50 is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

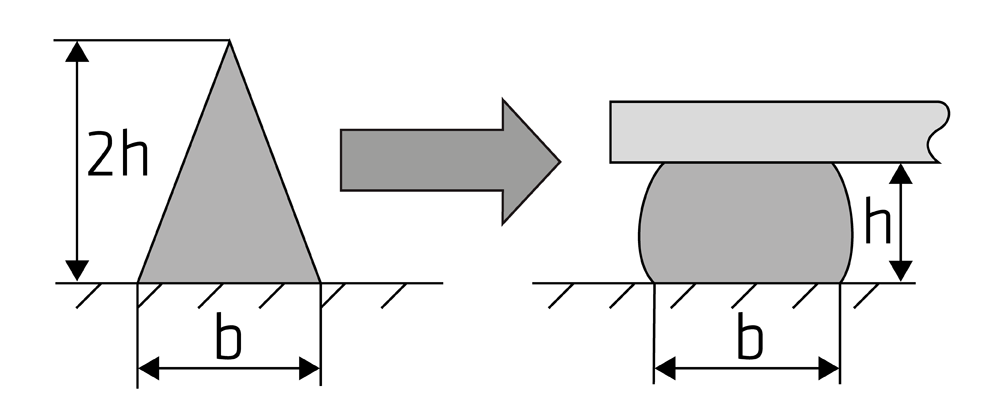

Application Information Surface Preparation Surfaces must be clean, dry and free from grease, oil, dust and contaminants. Surface treatment depends on the specific nature of the substrates and is crucial for a long lasting bond. Application Sikaflex-554 + SikaBooster S-50 need to be processed with an adequate dispensing system. The mixer type needs to be respected (see table Typical Product Data). To ensure a uniform thickness of the bondline it is recommend to apply the adhesive in form of a triangular bead (see figure 1).

Figure 1: Recommended bead configuration

The open time is significantly shorter in hot and humid climate. The parts must always be joint within the open time. As a rule of thumb, a change of + 10 °C reduces the open time by half. Tooling and finishing Tooling and finishing must be carried out within the open time of the adhesive. We recommend the use of Sika Tooling Agent N. Other finishing agents must be tested for suitability and compatibility. Removal Uncured Sikaflex-554 + SikaBooster S-50 may be removed from tools and equipment with Sika Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. |