DESIGNED FOR SIKA POWERCURE – HIGH SPEED PERFORMANCE IN ALMOST EVERY CLIMATE SikaTack ELITE provides 30 minutes Minimum Drive Away Time and cures to OEM Level within just 60 minutes. It is applied with the Sika PowerCure Dispenser and can be used all year round for mobile or in house applications.

SikaTack ELITE has been tested according to FMVSS 212 with 95th percentile dummies. - 30 min Minimum Drive Away Time, acc. FMVSS 212 / 95 th percentile dummies

- Enables fast, robust ADAS calibration

- Cured to Automotive OEM Level within 60 minutes almost independent of climate

- Automotive OEM quality

- Compatible with all car makes thanks to Sika’s all-in-one modulus technology

|

PRODUCT BENEFITS - 30 min Minimum Drive Away Time, acc. FMVSS 212 / 95th percentile dummies

- Enables fast, robust ADAS calibration

- Cured to Automotive OEM Level within 60 minutes almost independent of climate

- Automotive OEM quality

- Compatible with all car makes thanks to Sika’s all-in-one modulus technology

Usage SikaTack ELITE is suitable for experienced professional users only. This product and related process information is designed for Automotive Glass Replacement. For other applications, tests with actual substrates and conditions have to be performed to ensure adhesion and material compatibility. |

Typical Product Data| Chemical base | | Polyurethane | | Colour (CQP001-1) | | Black | | Cure mechanism | | Moisture-curing A | | Density (uncured) | | 1.3 kg/l | | Non-sag properties | | Very good | | Application temperature | productambient | 5 ─ 35 °C -10 ─ 35 °C | | Open time (CQP526-1) | | 8 minutes B | | Curing speed (CQP049-1) | | See table 1 | | Shore A hardness (CQP023-1 / ISO 48-4) | | 60 | | Tensile strength (CQP036-1 / ISO 527) | | 7 MPa | | Elongation at break (CQP036-1 / ISO 527) | | 300 % | | Tear propagation resistance (CQP045-1 / ISO 34) | | 10 N/mm | | Tensile lap-shear strength (CQP046-1 / ISO 4587) | | 5 MPa | | Minimum Drive Away Time (cars) according FMVSS 212 (CQP511-1) | with airbag | 30 minutes C / D | | Cured to OEM level (CQP046-1 / ISO 4587) | | 60 minutes B | | Insulation resistance (CQP079-2 / DIN IEC 60167) | | Low conductive | | Shelf life | | 9 months E |

| CQP = Corporate Quality Procedure | A)Provided by PowerCure B)23 °C / 50 % r. h. | | C)Details about MDAT contact Sika | D)-10 ─ 35 °C E)Storage below 25 °C |

|

Technical Information CURE MECHANISM SikaTack ELITE cures by reaction with the accelerator. | Time [min] | Strength [MPa] | | 60 | 1.5 | | 120 | 3 |

Table 1: Lap shear strength (CQP 046-1) at 23 °C / 50 % r.h.

CHEMICAL RESISTANCE SikaTack ELITE is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents.

|

Application Information Surface Preparation Surfaces must be clean, dry and free from grease, oil, dust and contaminants.

The bond faces must be treated according Sika's All Black installation process. Further information on the application and use of Pre-treatments, can be found in the corresponding Product Data Sheet.

Glass without ceramic coatings need proper UV protection. Application Setup the PowerCure Dispenser according the PowerCure User Manual. If the application is discontinued for more than 2 minutes, the mixer needs to be replaced. Consider that the viscosity will increase at low temperature. For easy application, condition the adhesive at ambient temperature prior to use.

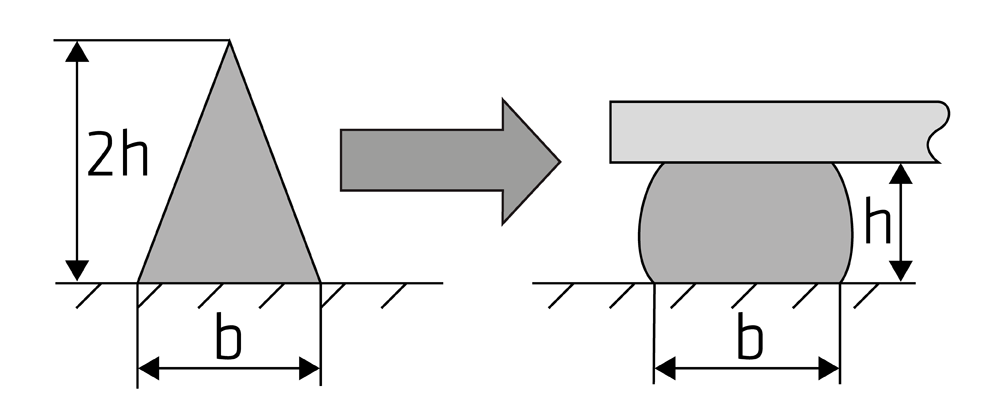

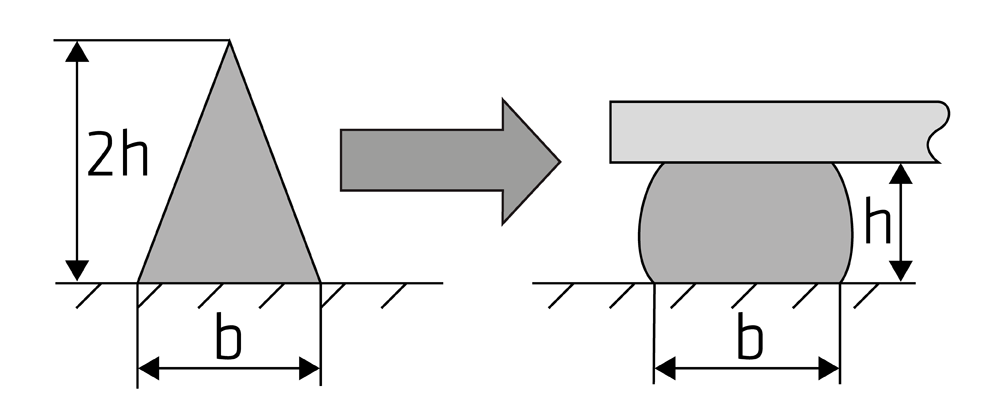

To ensure a uniform thickness of the bondline it is recommend to apply the adhesive in form of a triangular bead (see figure 1).

Figure 1: Compressing adhesive bead to final size

The open time is significantly shorter in hot and humid climate. The glass must always be installed within the open time. Never install a glass after the product has built a skin. Removal Uncured SikaTack ELITE can be removed from tools and equipment with Sika Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically.

Hands and exposed skin have to be washed immediately using hand wipes such as Sika Cleaner-350H cleaning towels or a suitable industrial hand cleaner and water. Do not use solvents on skin! |

The above design is only a sample of the options available, for reference purposes only. Our policy of continuous improvement may result in a change of specifications without notice. If any discrepencies might be between the data sheet values and standards, we reserve the rights to make technical changes. Our company will not be held responsible, as all or any of pictures, drawings, weights and dimensions details or other elements in this document are only indicative and must not be considered contractual. Contact our sales team for other specifications or custom made products.

Contact our sales team for other specifications or custom made products.