| Sikaflex-291i is a non-sag 1-component polyurethane sealant specifically developed for the marine market, which cures on exposure to atmospheric moisture. Sikaflex-291i meets in addition the low spread of flame requirements set out by the International Maritime Organisation (IMO). - Wheelmark approved

- 1-component formulation

- Highly elastic

- Low odour

- Non-corrosive

- Can be painted

- Bonds well to a wide variety of marine substrates

- Solvent free

- Very low VOC

- Low isocyanate content

|

PRODUCT BENEFITS - Wheelmark approved

- 1-component formulation

- Highly elastic

- Low odour

- Non-corrosive

- Can be painted

- Bonds well to a wide variety of marine substrates

- Solvent free

- Very low VOC

- Low isocyanate content

Usage Sikaflex-291i is a multipurpose product used in marine constructions. It is suitable for making elastic, vibration-resistant joint seals, and can also be used for a variety of interior sealing applications. Sikaflex-291i bonds extremely well to the materials commonly used in marine construction like wood, metals, metal primers and paint coatings (2-C systems), ceramic materials and plastics (GRP, etc.). Sikaflex-291i must not be used to seal plastics that are prone to stress cracking (e.g. PMMA, PC, etc.). This product is suitable for experienced professional users only. Test with actual substrates and conditions have to be performed to ensure adhesion and material compatibility. Packaging | Mini Unipack | 70 ml | | Cartridge | 300 ml | | Unipack | 400 ml |

|

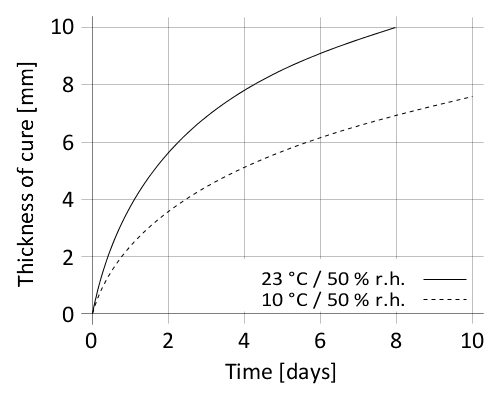

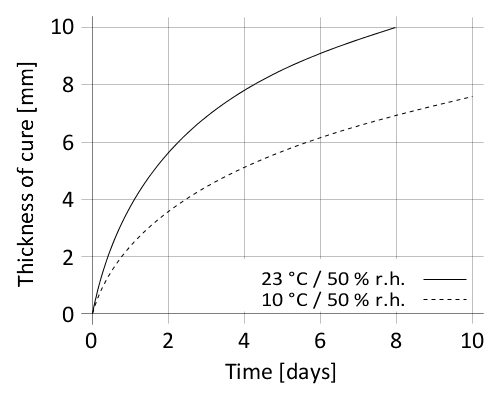

Typical Product Data| Chemical base | | 1-component polyurethane | | Colour (CQP001-1) | | White, grey, black | | Cure mechanism | | Moisture-curing | | Density (uncured) | depending on color | 1.3 kg/l | | Non-sag properties | | Good | | Application temperature | ambient | 10 ─ 40 °C | | Skin time (CQP019-1) | | 60 minutes A | | Open time (CQP526-1) | | 45 minutes A | | Curing speed (CQP049-1) | | (see diagram) | | Shrinkage (CQP014-1) | | 2 % | | Shore A hardness (CQP023-1 / ISO 48-4) | | 40 | | Tensile strength (CQP036-1 / ISO 527) | | 1.8 MPa | | Elongation at break (CQP036-1 / ISO 527) | | 700 % | | Tear propagation resistance (CQP045-1 / ISO 34) | | 7 N/mm | | Service temperature (CQP513-1) | 4 hours1 hour | -50 ─ 90 °C 120 °C 140 °C | | Shelf life | | 12 months B |

| CQP = Corporate Quality Procedure | A)23 °C / 50 % r. h. B)(storage below 25 °C |

|

Technical Information CURE MECHANISM Sikaflex-291i cures by reaction with atmospheric moisture. At low temperatures the water content of the air is generally lower and the curing reaction proceeds somewhat slower (see diagram 1).

Diagram 1: Curing speed for Sikaflex-291i

CHEMICAL RESISTANCE Sikaflex-291i is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents.

|

Application Information Surface Preparation Surfaces must be clean, dry and free from grease, oil and dust. Surface treatment depends on the specific nature of the substrates and is crucial for a long lasting bond. Suggestions for surface preparation may be found on the current edition of the appropriate Sika Pre-Treatment Chart. Consider that these suggestions are based on experience and have in any case to be verified by tests on original substrates. Application Sikaflex-291i can be processed between 10 °C and 40 °C but changes in reactivity and application properties have to be considered. The optimum temperature for substrate and sealant is between 15 °C and 25 °C. Sikaflex-291i can be processed with hand, pneumatic or electric driven piston guns. Tooling and finishing Tooling and finishing must be carried out within the skin time of the sealant. It is recommended using Sika Tooling Agent N. Other finishing agents must be tested for suitability and compatibility prior the use. Removal Uncured Sikaflex-291i can be removed from tools and equipment with Sika Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. Hands and exposed skin have to be washed immediately using Sika Cleaner-350H cleaning towels or a suitable industrial hand cleaner and water. Do not use solvents on skin! Overpainting Sikaflex-291i can be best painted after formation of a skin. Painting could be improved by treating the joint surface with Sika Aktivator-100 or Sika Aktivator-205 prior to paint process. If the paint requires a baking process (> 80 °C), best performance is achieved by allowing the sealant to fully cure first. All paints have to be tested by carrying preliminary trials under manufacturing conditions.

The elasticity of paints is usually lower than that of sealants. This could lead to cracking of the paint in the joint area. |

The above design is only a sample of the options available, for reference purposes only. Our policy of continuous improvement may result in a change of specifications without notice. If any discrepencies might be between the data sheet values and standards, we reserve the rights to make technical changes. Our company will not be held responsible, as all or any of pictures, drawings, weights and dimensions details or other elements in this document are only indicative and must not be considered contractual. Contact our sales team for other specifications or custom made products.

Contact our sales team for other specifications or custom made products.