Sikaflex-271 PowerCure, Accelerated Glazing Adhesive, Exterior, Black, 600 mL

SIKA

Sika is a global leader in specialty chemicals for the construction and industrial sectors. The company develops and supplies innovative products and systems for bonding, sealing, damping, reinforcing, and protecting structures. With a strong focus on sustainability and performance, Sika serves a wide range of applications including concrete production, waterproofing, roofing, flooring, and structural strengthening.

Read more| Accelerated glazing adhesive Sikaflex-271 PowerCure is an accelerated elastic polyurethane adhesive for glazing and vehicle-glass-replacement applications. Suitable for bonding materials relevant for direct glazing such as paints, glass, ceramic frits, painted and e-coated surfaces in commercial-vehicle production and repair. Curing of Sikaflex-271 PowerCure is accelerated by Sika’s PowerCure technology which makes it largely independent of atmospheric conditions.

| |||||||||||||||||||||||||||||||||||||||||||||

PRODUCT BENEFITS

UsageSikaflex-271 PowerCure is designed especially for manual direct-glazing application and vehicle-glass replacement in commercial vehicles. Thanks to the PowerCure Technology Sikaflex-271 PowerCure exhibits a fast strength and adhesion build-up. This product is suitable for experienced professional users only. Test with actual substrates and conditions have to be performed to ensure adhesion and material compatibility.Packaging

| |||||||||||||||||||||||||||||||||||||||||||||

Typical Product Data

| |||||||||||||||||||||||||||||||||||||||||||||

Technical Information CURE MECHANISM Sikaflex-271 PowerCure cures by reaction with moisture provided by the accelerator paste and largely independent from atmospheric moisture. For typical strength build up data see table below. Time [h] Tensile lap-shear strength at 23 °C [MPa] 1 0.7 2 3.5 Table 1: Strength build-up of Sikaflex-271 PowerCure CHEMICAL RESISTANCE Sikaflex-271 PowerCure is generally resistant to fresh water, seawater, diluted acids and diluted caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils; not resistant to organic acids, glycolic alcohol, concentrated mineral acids and caustic solutions or solvents. | |||||||||||||||||||||||||||||||||||||||||||||

Application Information Surface Preparation Surfaces must be clean, dry and free from grease, oil and dust. Surface treatment depends on the specific nature of the substrates and is crucial for a long lasting bond. All pre-treatment steps must be confirmed by preliminary tests on original substrates considering specific conditions in the assembly process. Application Setup the PowerCure Dispenser according to the PowerCure User Manual. If the application is discontinued for more than 2 minutes, the mixer needs to be replaced.

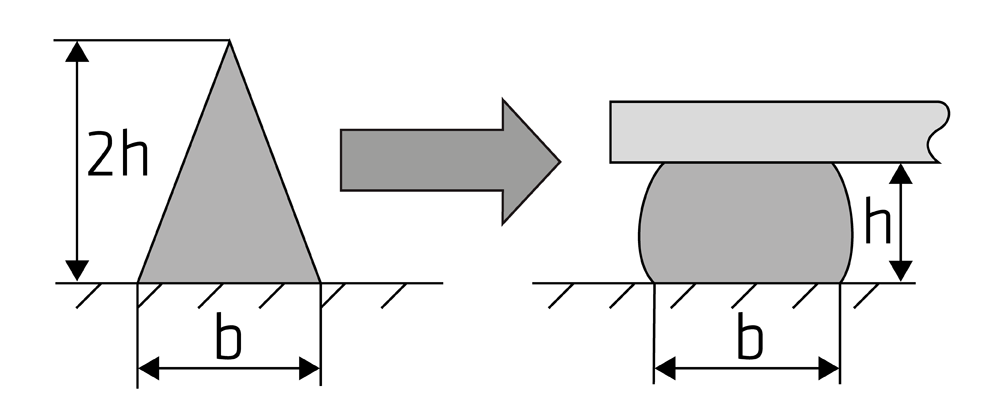

Figure 1: Recommended bead configuration Removal Uncured Sikaflex-271 PowerCure can be removed from tools and equipment with Sika Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. Hands and exposed skin have to be washed immediately using hand wipes such as Sika Cleaner-350H or a suitable industrial hand cleaner and water. Do not use solvents on skin. |