Sikasil FS-665 SL, Self-Levelling Fire-Rated Sealant, Interior & Exterior, Black, 25 kg

SIKA

Sika is a global leader in specialty chemicals for the construction and industrial sectors. The company develops and supplies innovative products and systems for bonding, sealing, damping, reinforcing, and protecting structures. With a strong focus on sustainability and performance, Sika serves a wide range of applications including concrete production, waterproofing, roofing, flooring, and structural strengthening.

Read more| Self-levelling fire-rated sealant Sikasil FS-665 SL is a fire-rated, self-levelling, low-modulus, silicone sealant with good adhesion to a wide range of porous and nonporous substrates. It is mainly used for floor joints and where fire rated sealing products are required.

| |||||||||||||||||||||||||||||||||||||||||||||||||||

PRODUCT BENEFITS

UsageSikasil FS-665 SL can be used in horizontal joints between curtain wall facades and floor slabs to prevent spreading of fire and smoke. It is also suitable in other industrial applications where good UV, thermal and fire resistance are required. This product is suitable for professional experienced users only. Tests with actual substrates and conditions have to be performed ensuring adhesion and material compatibility.Packaging

| |||||||||||||||||||||||||||||||||||||||||||||||||||

Typical Product Data

| |||||||||||||||||||||||||||||||||||||||||||||||||||

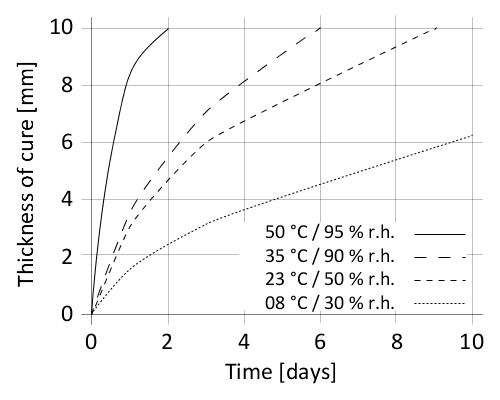

Technical Information CURE MECHANISM Sikasil FS-665 SL cures by reaction with atmospheric moisture. At low temperatures the water content of the air is generally lower and the curing reaction proceeds somewhat slower (see diagram 1). Diagram 1: Curing speed Sikasil FS-665 SL | |||||||||||||||||||||||||||||||||||||||||||||||||||

Application Information Surface Preparation Surfaces must be clean, dry and free from grease, oil and dust. Surface treatment depends on the specific nature of the substrates and is crucial for a long lasting bond. Application The optimum temperature for substrate and sealant is between 15 °C and 25 °C. Joints deeper than 15 mm must be avoided. Removal Uncured Sikasil FS-665 SL can be removed from tools and equipment with Sika Remover-208 or another suitable solvent. Once cured, the material can only be removed mechanically. Hands and exposed skin have to be washed immediately using hand wipes such as Sika Cleaner-350H or a suitable industrial hand cleaner and water. Application Limits To exclude materials influencing Sikasil FS-665 SL, all materials such as gaskets, tapes, setting blocks, sealants, etc., in direct and indirect contact have to be approved by Sika in advance. Where two or more different reactive sealants are used, allow the first to cure completely before applying the next. Sikasil FS-665 SL may only be used in combination with structural glazing applications after a detailed examination of the corresponding project details. Do not use Sikasil FS-665 SL on PMMA and PC elements as it may cause environmental stress cracking (crazing). |