2-part polyurethane grout for continuous embedded tracks (shore A 40)

Sika® Icosit® KC 340/35 is a flexible two-part polyurethane polymer resin grout that can be applied manually or by machine.

It is designed as a vibration absorbing, load-bearing, flexible grout for the continuous fixing of embedded grooved rails.

Particularly suitable for embedded (floating) rail designs.

-

Light axle loads and high deflection.

-

Noise and vibration suppression.

-

More uniform load distribution into substructure.

-

Watertight undersealing.

-

Flexible, elastic (shore A 40).

-

Damping, compressible.

-

Good electrical insulation against stray currents.

-

Excellent adhesion on various substrates.

-

Levels out tolerances.

-

Suitable as a powerful, shear-resistant adhesive.

-

Absorbs dynamic stresses and prolongs the life of concrete substructure.

-

Insensitive to moisture.

-

Long durability, less maintenance.

|

Usage

As a noise and vibration reducing grout for continuous embedded tram or LRT track sections and road crossing applications.

Advantages

- Light axle loads and high deflection.

- Noise and vibration suppression.

- More uniform load distribution into substructure.

- Watertight undersealing.

- Flexible, elastic (shore A 40).

- Damping, compressible.

- Good electrical insulation against stray currents.

- Excellent adhesion on various substrates.

- Levels out tolerances.

- Suitable as a powerful, shear-resistant adhesive.

- Absorbs dynamic stresses and prolongs the life of concrete substructure.

- Insensitive to moisture.

- Long durability, less maintenance.

Packaging

| | Manual application | Machine application | | Part A | 8,9 kg container | 160 kg drum | | Part B | 1,1 kg container | 19,2 kg container | | A + B | 10 kg | 179,2 kg |

Refer to current price list for packaging variations.

|

Technical Information

Shore A Hardness

| 40 ± 5 (after 28 days) | (ISO 868) |

Shore hardness assists with material identification and assessing the curing progress on site.

Compressive stiffness

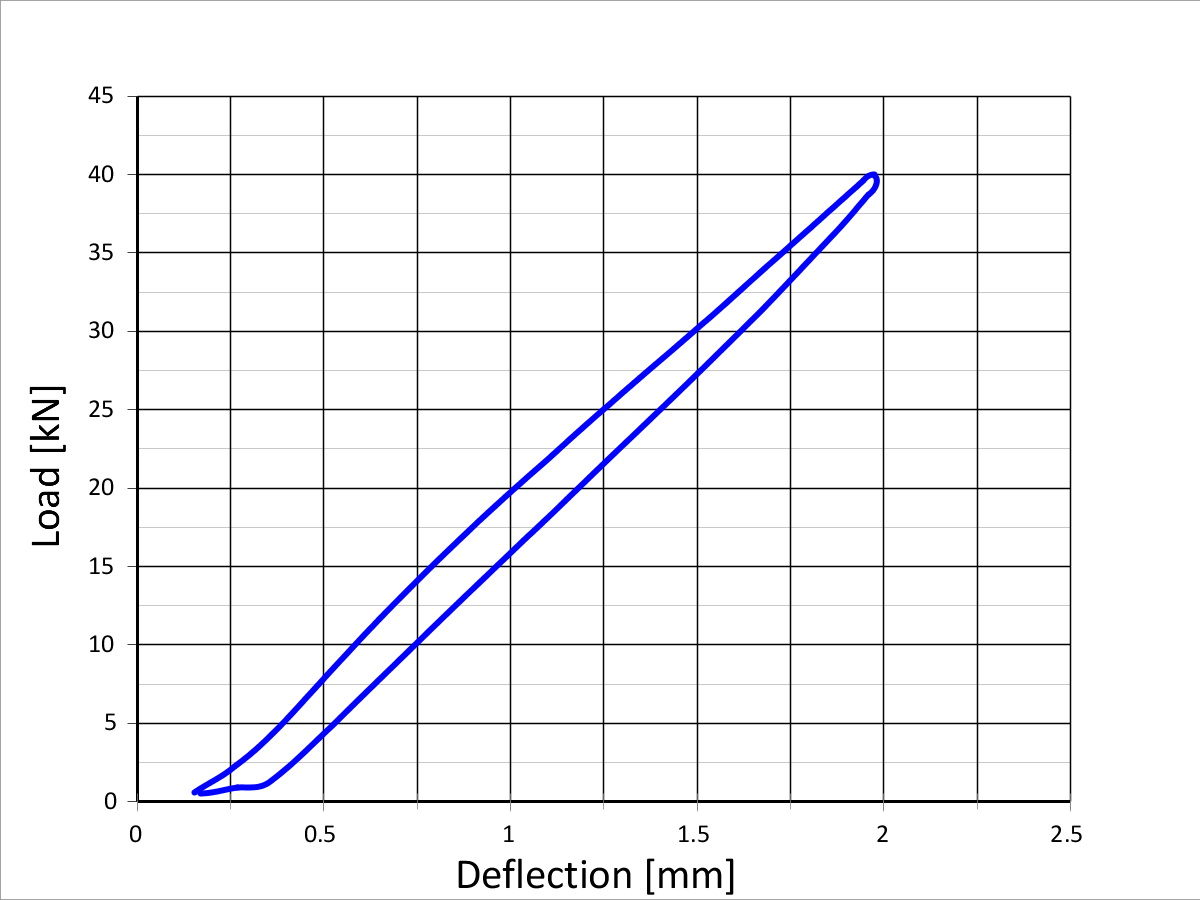

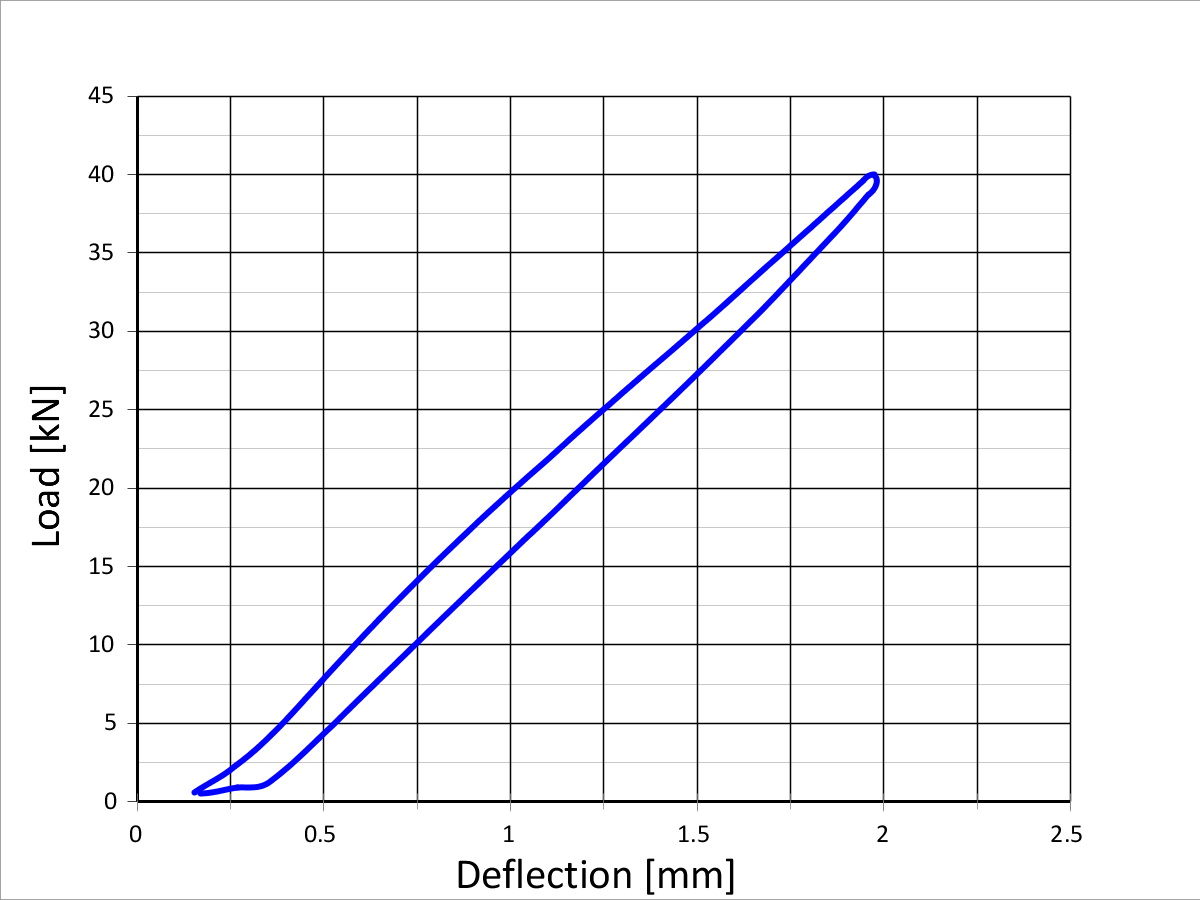

Load-Deflection Diagram

Static stiffness determined according to DIN 45673-1.

Dimensions of test specimen 1000 × 180 × 25 mm;

Spring index kstat = 25 kN/mm (± 10 %), determined as per the secant method between 4 and 32 kN.

Electrical Resistivity

| ~1,5 × 109 Ω·m | (DIN VDE 0100-610 and DIN IEC 93) |

Service Temperature

-40 °C minimum / +80 °C maximum

Short term: +150 °C maximum

Chemical Resistance

Long-term resistant against:

- Water

- Most detergents

- Sea water

- Alkaline water

Short-term resistant against:

- Mineral oils, diesel fuel, vegetable and animal fat

Short-term or no resistance against:

- Organic solvents (ester, ketone , aromates) and alcohol

- Solvents and thinners

- Strong lyes and acids

Contact Sika Technical Services for specific information.

|

Application Information

Mixing Ratio

Part A : Part B = 100 : 12 (parts by weight)

Layer Thickness

15 mm minimum

60 mm maximum

Product Temperature

Condition product parts before application preferably at ~+15 °C to assist with flow and curing speed

Ambient Air Temperature

+5 °C minimum / +35 °C maximum

Relative Air Humidity

90 % maximum

Substrate Temperature

+5 °C minimum / +35 °C maximum

Substrate Moisture Content

Dry to matt damp

Pot Life

~11–12 minutes at +20 °C

After this time, the mixture becomes unusable.

Higher temperatures will shorten pot life.

Curing Time

Tack-free ~2 hours at +20 °C

Trafficable ~24 hours at +20 °C

Curing Rate

| Shore A | Curing Temperature | | Curing Time | 5 °C | 23 °C | 35 °C | | 2 hours | - | ~10 | ~15 | | 3 hours | - | ~15 | ~20 | | 4 hours | - | ~20 | ~25 | | 7 hours | - | ~25 | ~25 | | 1 day | ~20 | ~30 | ~30 | | 2 days | ~25 | ~30 | ~30 | | 7 days | ~30 | ~30 | ~30 | | 14 days | ~30 | ~30 | ~30 |

Waiting Time / Overcoating

Waiting time between primer and Sika® Icosit® KC 340/35 at 20 °C:

| | Minimum | Maximum | | Icosit® KC 330 Primer | 1 hour | 3 days | | Sikadur®-32 + | 24 hours | 7 days |

|

The above design is only a sample of the options available, for reference purposes only. Our policy of continuous improvement may result in a change of specifications without notice. If any discrepencies might be between the data sheet values and standards, we reserve the rights to make technical changes. Our company will not be held responsible, as all or any of pictures, drawings, weights and dimensions details or other elements in this document are only indicative and must not be considered contractual. Contact our sales team for other specifications or custom made products.

Contact our sales team for other specifications or custom made products.