Multipurpose hot melt pressure sensitive adhesive SikaMelt-230 is a multipurpose pressure sensitive hot melt adhesive based on thermoplastic rubber for a wide range of applications. It is mainly used for the production of technical tapes. Another typical application is the assembly of felt materials for insulation purposes. - Good tack

- High peel strength

- Very high cohesion

|

PRODUCT BENEFITS - Good tack

- High peel strength

- Very high cohesion

Usage SikaMelt-230 is designed to adhere to papers, films and metal foils, textiles, foams and a wide variety of other materials. It is especially suitable for the manufacturing of self-adhesive products and components. SikaMelt-230 is not to be used on substrates containing monomeric plasticiser.

This product is suitable for experienced professional users only. Tests with actual substrates and conditions have to be performed ensuring adhesion and material compatibility. |

Typical Product Data| Chemical base | | Thermoplastic rubber | | Colour (CQP001-1) | | Yellowish, clear | | Cure mechanism | | Physical hardening | | Density | | 0.99 kg/l | | Viscosity (by Brookfield) | 160 °C | 18 000 mPa·s | | Softening temperature (CQP538-5) | | 95 °C | | Application temperature | short term max. 1h | 150 - 170 °C 200 °C A | | SAFT (CQP560-1) | | 67 °C | | Peel strength (CQP568-1) | | 35 N/25 mm B | | Shelf life | | 24 month |

| CQP = Corporate Quality Procedure | A)only valid for nozzle B)23 °C / 50 % r. h. |

|

Technical Information CURE MECHANISM SikaMelt-230 is a physically hardening adhesive.

CHEMICAL RESISTANCE SikaMelt-230 is resistant to aqueous surfactant, weak acids and caustic solutions.

The chemical resistance is influenced by several factors such as chemical composition, concentration, period of exposure and temperature. Therefore a project related testing in case of chemical or thermal exposure is required.

|

Application Information Surface Preparation Surfaces must be clean, dry and free from grease, oil and dust.

Based on the surface and type of material, a physical or chemical pre-treatment might be required. Type of pre-treatment must be determined by preliminary tests. Application With adequate processing equipment SikaMelt-230 can be applied directly or by transfer method.

It can be applied as film, dot, bead or spray application. For automated applications a suitable filter system is required.

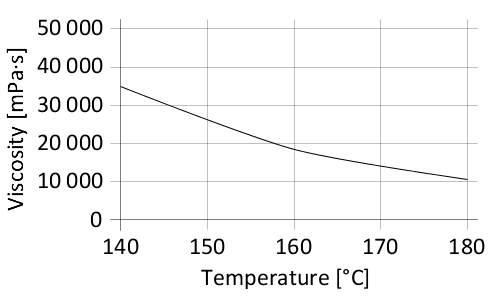

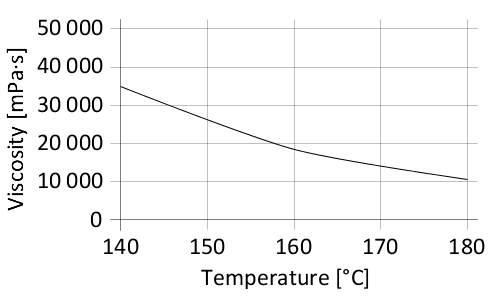

Due to the better adhesion performance the direct method is usually chosen whenever possible. The transfer method is often used in combination with substrates that are porous and absorbing such as foams or when they are sensitive to high temperature such as thin PE films. To protect the adhesive surface against dust, light and oxygen it is necessary to cover the adhesive film with silicone coated paper or foil. To meet the required application properties the adhesive viscosity can be adjusted by adapting the application temperature (see diagram 1).

Diagram 1: Viscosity as function of temperature

During breaks SikaMelt-230 is to be processed as follows:

For breaks ≥ 1 h the heating needs to be lowered to 80 °C and for breaks ≥ 4 h the heating needs to be switched off.

To ensure a constant quality during the whole production process it is recommended to protect the adhesive in the melting tank with nitrogen or carbon dioxide (to avoid possible reaction of the product with oxygen).

For advice on selecting and setting up suitable processing equipment contact the System Engineering Department of Sika Industry. Removal SikaMelt-230 may be removed from tools and equipment with Sika Remover-208 or another suitable solvent.

Hands and exposed skin have to be washed immediately using hand wipes such as Sika Cleaner-350H or a suitable industrial hand cleaner and water. Do not use solvents on skin. STORAGE CONDITIONS SikaMelt-230 has to be stored at temperature below 40 °C in a dry place.

For transportation purposes, the storage temperature can be exceeded for a period of max. 4 weeks up to 60 °C. |

The above design is only a sample of the options available, for reference purposes only. Our policy of continuous improvement may result in a change of specifications without notice. If any discrepencies might be between the data sheet values and standards, we reserve the rights to make technical changes. Our company will not be held responsible, as all or any of pictures, drawings, weights and dimensions details or other elements in this document are only indicative and must not be considered contractual. Contact our sales team for other specifications or custom made products.

Contact our sales team for other specifications or custom made products.